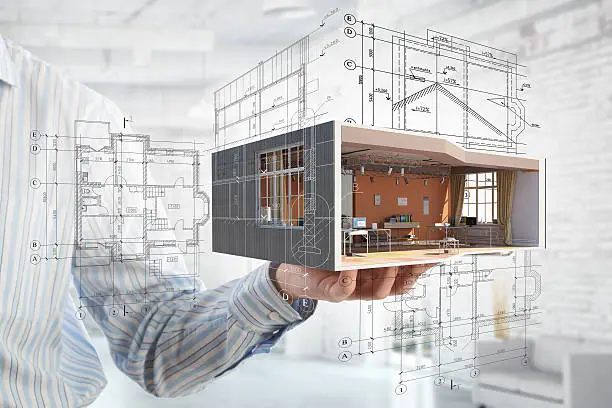

Virtual Assembly for Real-World Accuracy

Before construction begins, every element should fit perfectly--digitally. Virtual Assembly connects all the components of a building into the form of a 3D model that is coordinated, permitting teams to identify problems early and speed up the whole procedure. Thanks to the capabilities provided by BIM Coordinating Services, this method ensures accuracy and reduces costly mistakes, and helps to deliver projects precisely as they were planned in reality.

With the advent of digital change and digital transformation, the industry of construction industry has undergone a major shift. The traditional workflows are being replaced with digitally rich, virtual spaces in which buildings are designed, then reviewed, and then refined well before even a single brick can be laid. The concept of virtual assembly is changing the way precision is attainable in real-world construction. The core of this revolution is BIM Coordination Services, which integrates the physical and digital execution remarkably.

The Evolution of Construction Planning

In the past, construction depended upon 2D sketches, hand-written mark-ups, and a reactive approach to decisions. This has often led to inconsistent designs, miscommunications, as well as the possibility of errors on-site.

Virtual assembly flips the model upside down by creating everything in digital space before. Through BIM Coordination Services, all participants in the project can visualize and modify components in the virtual space, making sure that the product built will be precisely what is meant to be.

What Is Virtual Assembly?

Virtual assembly is the process prior to the construction of digitally creating every part of a building as if it were built on site. The system ensures that each element, including steel beams and vent ducts, is positioned precisely.

It is possible only by utilizing the extensive BIM Coordination Services, which combine structure, architecture, and MEP to create a clash-free, completely coordinated digital model.

Achieving Real-World Precision

Accuracy is among the most desired qualities of every construction job. It can affect costs, safety, as well as the longevity of.

In simulating the assembly process of all components before construction even begins, BIM Coordination Services help to identify any potential issues, prevent the waste of time and money, as well as reduce work-related rework. BIM Coordination Services provide real-time precision using simulation-based planning.

Clash Detection Before Construction

One of the biggest advantages that virtual assemblies offer is their ability to spot and fix conflicts early during the assembly process. Pipework, supports for structural support, as well as cabling, tend to be lightly packed in modern structures.

BIM Coordination Services use sophisticated clash detection procedures to identify any problems before material is ordered or even before the installation process begins. This helps clients avoid last-minute revisions or delays.

Enhancing Off-Site Fabrication

Virtual assembly can also support the growing demand for modular and prefabrication. If models are coordinated precisely, parts can be produced on-site and then installed without any adjustments.

BIM Coordination Services ensure this precision by aligning drawings from shops to the master model, ensuring that the prefabricated components are in alignment with the plan after they have arrived on site.

Reducing Waste and Material Costs

The process of reordering or ordering materials caused by measurement mistakes can be extremely costly as well as environmentally harmful. The accuracy of virtual modeling reduces this loss.

With BIM Coordination Services, material amounts can be directly extracted from the model. This gives accurate data to aid in procurement planning, budgeting, as well as the control of inventory.

Improving Construction Sequencing

Virtual assembly isn't all about precision in fitting; it's equally about the timing. Models that coordinate allow for better planning of building sequences, decreasing conflicts between tradesmen and enhancing productivity on the job site.

Utilizing BIM Coordination Services, contractors can visualize installation stages and improve workflows, making sure that the appropriate teams are at the correct place and at the correct time.

Training and Site Preparation

Virtual models are also useful training tools. Teams can practice installing installation procedures, comprehend complicated layouts, and get ready for work on-site more efficiently.

Through BIM Coordination Services, models are accessible via tablet computers or VR systems and give personnel at the site confidence in installing the systems right the first time.

Supporting Regulatory Compliance

Conformity with fire safety standards rules, access requirements, and the building code is vital to any building project. An exact, precise model helps comply with these requirements.

BIM Coordination Services ensure that the models meet all regulations and legal requirements and reduce the possibility of delays because of inadequate inspections or the need for revisions.

Post-Construction Benefits

Virtual assembly's advantages persist long after the transfer. Digital models provide invaluable data for facility managers, which allows the efficient maintenance of future upgrades, repairs, and extensions.

By utilizing a model developed by experts at BIM Coordination Services, building owners get a highly data-driven asset that can be used as a lifetime source of information for making informed decisions in the operational field.

Conclusion: Assembling the Future Digitally

With the development of buildings becoming more advanced, their margin of error shrinks. Virtual assembly, supported through powerful modeling and coordination, is an effective method of achieving the highest level of accuracy and precision in each project.

With the help of the use of trusted BIM Coordination Services, teams can anticipate problems, cut expenses, and produce better results. It's a matter of fact that the virtual environment becomes a testing site for the physical. This isn't just about seeing what's going to be built but also ensuring that it's constructed correctly, at first.